Have you ever wondered how industrial switches are crucial in increasing productivity in manufacturing plants and other industrial settings? These small components may seem insignificant, but they are essential for smooth operations and efficiency.

Organizations can’t think of running smoothly without industrial switches as they are vital in all departments for increasing productivity. How?

This article will discuss how industrial switches help increase productivity. Follow along!

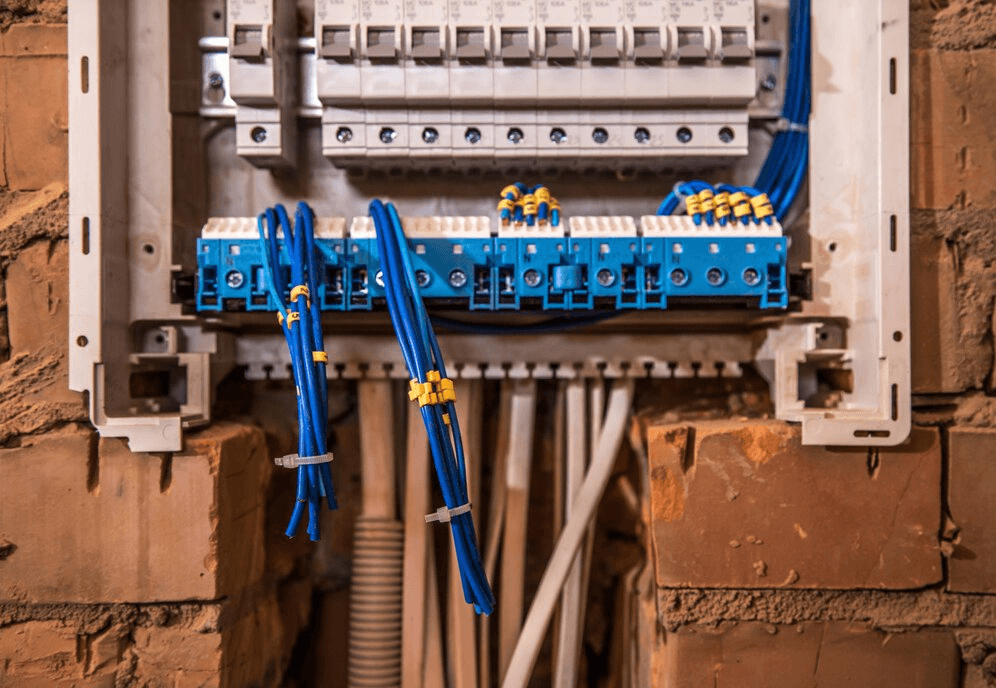

1. Reliable Communication Networks

In large factories, industrial switches function as swift messengers. They facilitate fast and dependable machine-to-machine communication.

Envision a factory where numerous machines perform various tasks, such as producing cars or packaging boxes. For these machines to function as a cohesive unit, they must communicate with one another. Industrial switches can help with that. They ensure these messages get to the suitable machines quickly at the right time.

For instance, a machine can communicate with another machine to begin its task when it completes its own. To maintain the smooth operation of the factory, this communication must occur without any mistakes or delays. Industrial switches ensure that these messages arrive at lightning speed so that the machines can keep up with the production rate.

These signals could be misdirected or take too long to reach their destination without an industrial switch. Production delays could result from this as the factory slows down. Nonetheless, industrial switches enable quick, dependable, and effective machine-to-machine communication, enabling the factory to produce more goods in a shorter amount of time.

Therefore, industrial switches are the stars of the manufacturing world, ensuring everything functions as it should.

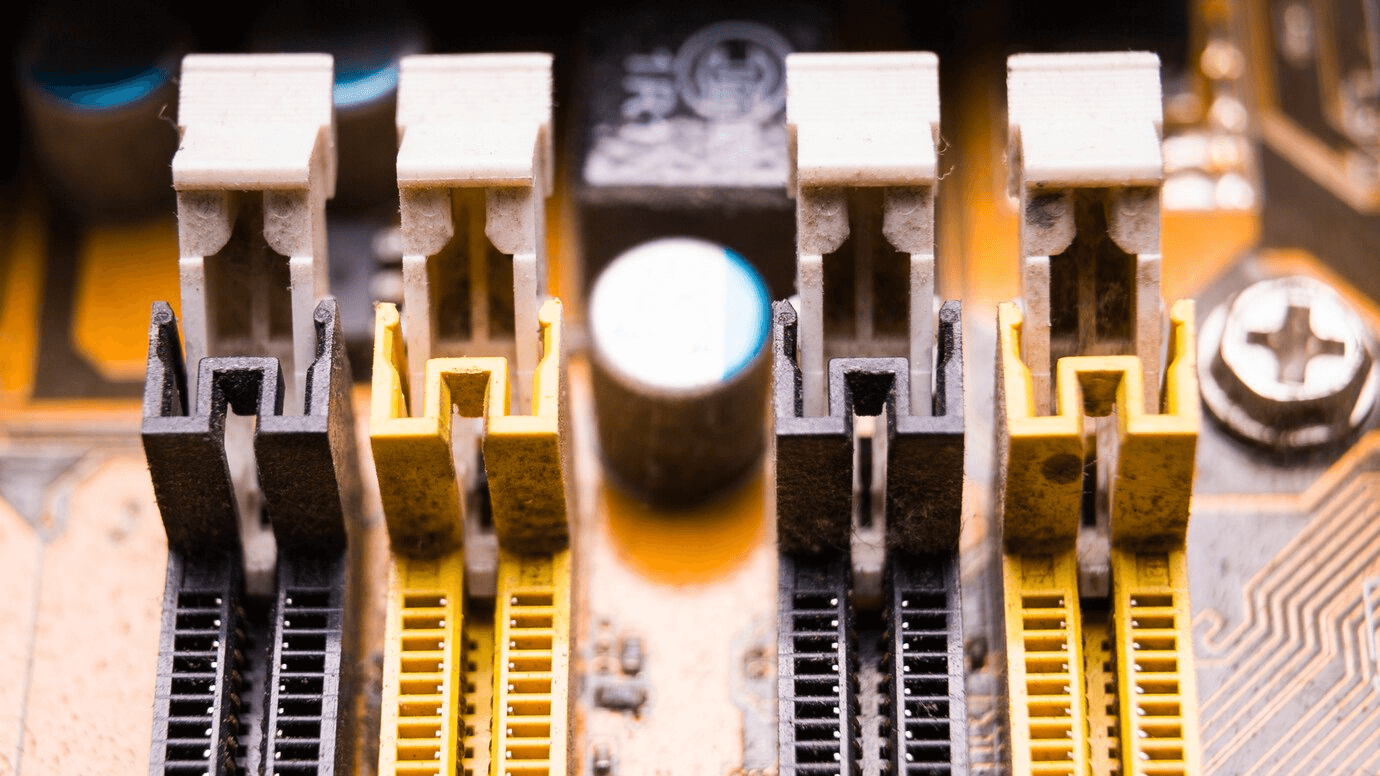

2. High-Speed Data Transmission

Thanks to industrial switches, machines, and computers can transmit and receive data at high speeds. Robots, for instance, must have excellent cooperative skills, the ability to monitor quality in real time, and the ability to maintain continuous operation. Machines might not cooperate, leading to sloppy or incorrect production if the switches aren’t fast enough.

Besides prioritizing data based on importance, these switches help divide data into lanes. It’s like giving an ambulance priority on the road. Thanks to this system, the most critical information will reach its intended recipients without delay or hiccups. In its absence, crucial messages risk overshadowing less important ones, which could cause production delays or errors.

Simply put, industrial switches are the equivalent of a factory’s lightning-fast, super-smart file organizers. Companies can accomplish more with less effort and faster results, which is great for cost-effectiveness and customer satisfaction.

3. Network Segmentation and Traffic Prioritization

Industrial switches divide the network into smaller roads or segments. As a result, the data flows more smoothly and systematically. Like traffic lights for different cars on the road, industrial switches prioritize the most critical data packets for the operations of your factory.

Imagine your factory network as a congested highway that is home to a variety of vehicles. While some only carry regular goods, others carry urgent packages. Industrial switches ensure urgent deliveries reach their destination by approving them. Regular orders have to wait.

By segmenting the network and allocating varying degrees of importance to different traffic, industrial switches help prevent delays and traffic bottlenecks. This implies that critical information, such as commands to operate machinery or monitor processes, can travel to its destination swiftly and error-free. This will improve your factory’s efficiency and smooth operation, increasing output and reducing production delays.

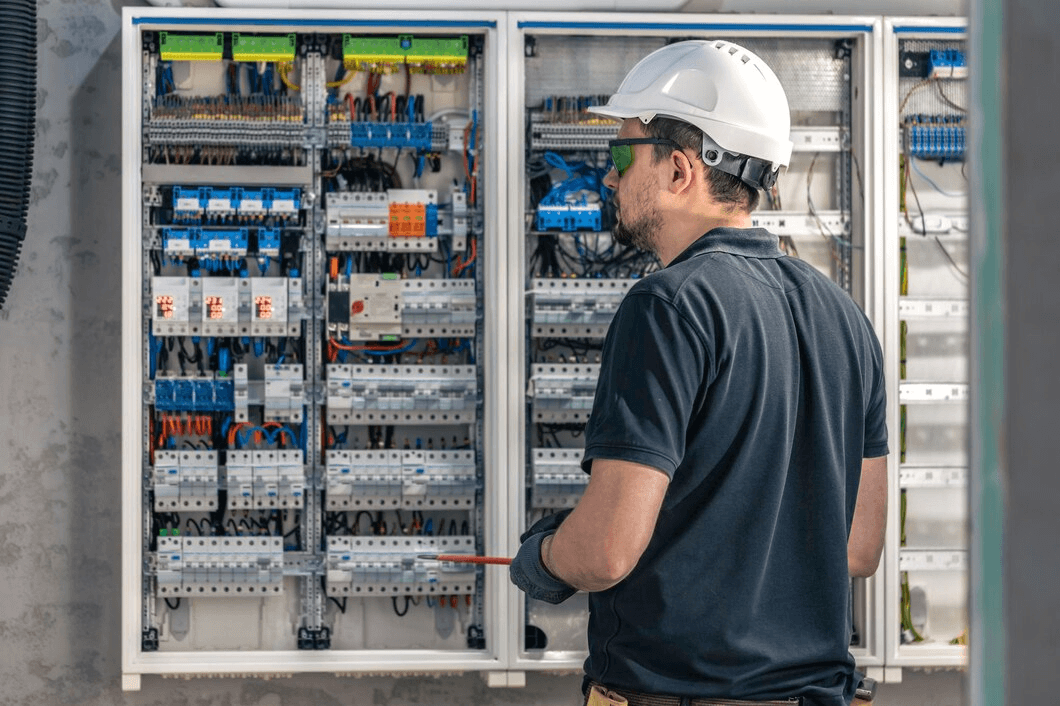

4. Resilience and Redundancy

Industrial switches are resilient enough to withstand harsh environments and unexpected issues without breaking down. Because of their sturdy construction, these switches can withstand heat and dust.

Envision a highway crowded with vehicles. The cars must find another route to continue traveling if a section of the road becomes shut. Industrial switches take similar actions.

If something goes wrong, they have backup plans. Thus, if a component of the network malfunctions, they swiftly identify an alternative route for the data to follow, guaranteeing uninterrupted operation.

This keeps companies and industries operating efficiently even in the face of difficulties. The switches take care of the network, so employees don’t need to stop what they’re doing to fix it.

5. Remote Management and Diagnostics

Modern industrial switches connect machines and help people manage them from far away. Imagine having a magic remote for all the switches in a factory. These switches can talk to this remote, telling it if everything is okay or something needs fixing.

If a switch notices a problem, it can send a message to the remote, alerting a human to come and solve the issue. This saves a lot of time because people can focus on fixing problems quickly instead of checking every machine manually.

These switches also have special powers to diagnose themselves. If something goes wrong with a switch, it can communicate precisely what’s happening, like how a doctor diagnoses an illness. This way, problems get fixed faster, and the factory keeps running smoothly.

Plus, the remote can be accessed from anywhere, even if you’re not at the factory. This means that someone sitting in an office miles away can still monitor everything and ensure the factory stays productive.

Conclusion

Industrial switches boost productivity by ensuring reliable communication, fast data transfer, and resilience in harsh environments.

With features like network segmentation, remote management, and integration with IoT, they optimize processes and minimize downtime, ultimately helping industries operate more efficiently and profitably.